Product Description

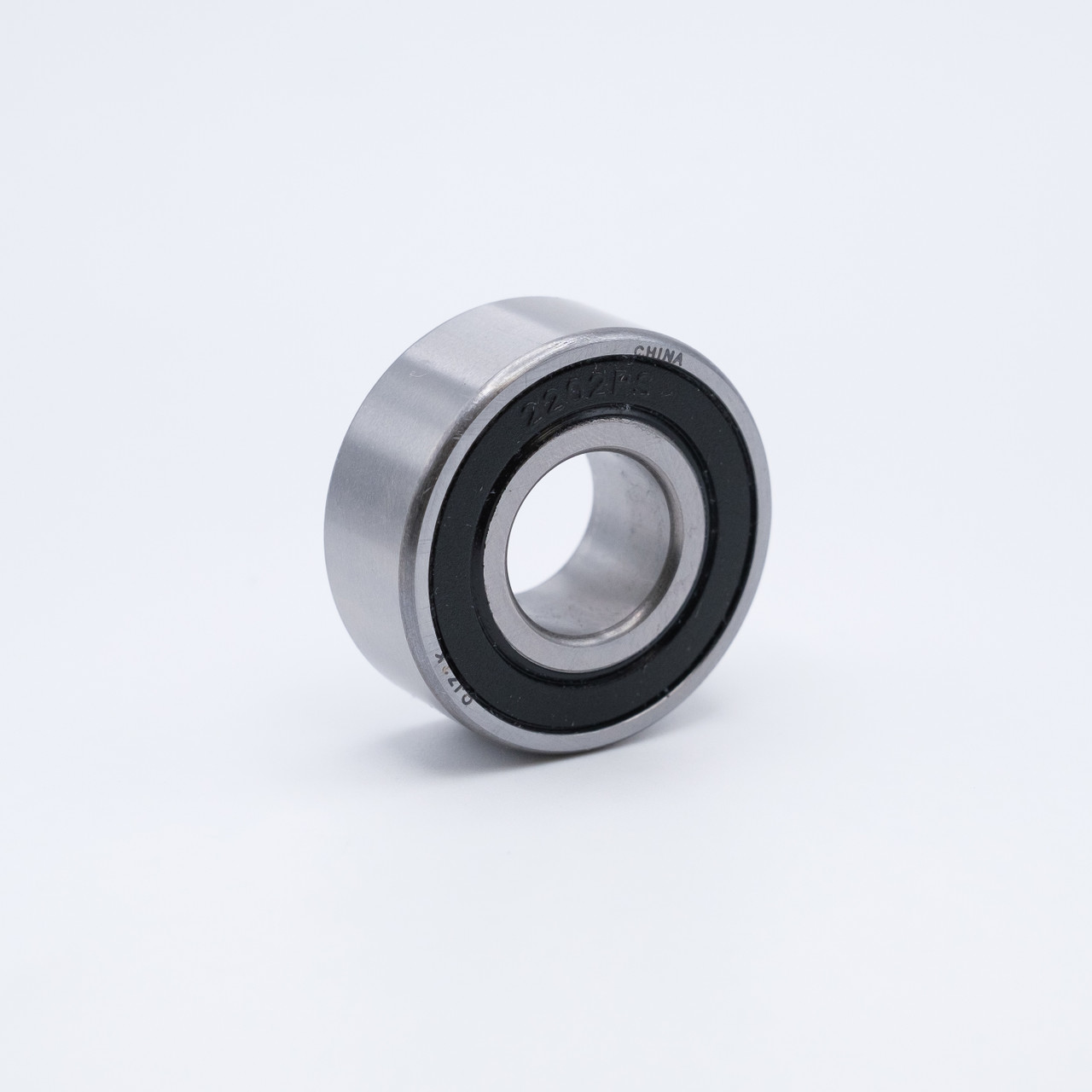

2210-2RS Self Aligning Ball Bearing

Key Features

2210-2RS is a Precision ABEC1 Self Aligning Ball Bearing with both sides Rubber Sealed and is pre-lubricated with Grease allowing for use upon delivery. 2210-2RS has a straight bore for fitting on a conventional cylindrical shaft and a steel cage with evenly spaced balls for reduced friction, vibration, and noise. Our 2200 Series Self Aligning Ball Bearings have two rows of balls with a common, sphered raceway and permit angular misalignment of the shaft. This allows for applications subject to shaft deflections or misalignments between the shaft and housing.

Match Numbers / Interchange Numbers

2210EEG15, 2210-2RSTV, 2210RS, 2210.2RSJ1, U150W, NLDJ50, 3110-00-156-5097, D0170300820, P3210

Applications / Industries

2210-2RS Self Aligning Ball Bearings are used in a range of applications from Papermaking Machines, Fans, Wind Turbines, Mills, Process Pumps, Luggage Conveyor Systems, Shredders, Ring Spinning Machines, Automotives, Among Others.

What are Self Aligning Ball Bearings?

Self-aligning ball bearings generate less friction than other styles of bearings, which allows them to run at higher speeds without building up as much heat. As a result, self-aligning ball bearings are more suitable for low- to medium-sized loads. In a self-aligning bearing, the inner ring has two raceways and the outer ring has a single spherical raceway with its center of curvature coincident with the bearing axis. This allows the axis of the inner ring, balls and cage to deflect around the bearing center to automatically correct misalignment caused by housing and shaft machining or installation error.

What are Rolling-Element Bearings?

Rolling-element bearings, commonly called rolling bearings, are bearings that carry a load by utilizing “rolling elements” between two concentric, grooved rings called races. The motion of the bearing races allows for the rolling elements to move with very little resistance and with little slide variance.

Some common types of rolling elements include ball, cylindrical, spherical, barrel, needle, spindle, or tapered.

What is the Difference Between Open, Shielded, and Sealed Rolling Bearings?

The main difference between open and sealed/ shielded bearings is the application of lubrication. The main difference between sealed and shielded bearings is the presence of a protective enclosure.

- Sealed and shielded bearings are lubricated with grease in the bearing factory. However, a rubber sealed bearing protects the bearing by using a seal that contacts the inner and outer race. This provides superior protection at the cost of operating speed and temperature.

- Open bearings are meant to be lubricated with light oil, with periodic reapplication of lubrication, based on use.

- Shielded rolling bearings contain an enclosure that helps to protect the working parts of the bearing from environmental debris that may be introduced and would otherwise reduce the ball bearing speed and lifespan. This metal shield is stamped onto the bearing and only contacts the outer ring, this allows for protection without sacrificing operating speed or temperature.