Product Description

6300-ZZC3 bearing is Precision Radial Ball Bearing with C3 class and Both Sides Metal Shielded and pre-lubricated with bearing grease to allow them to be ready to use upon arrival.

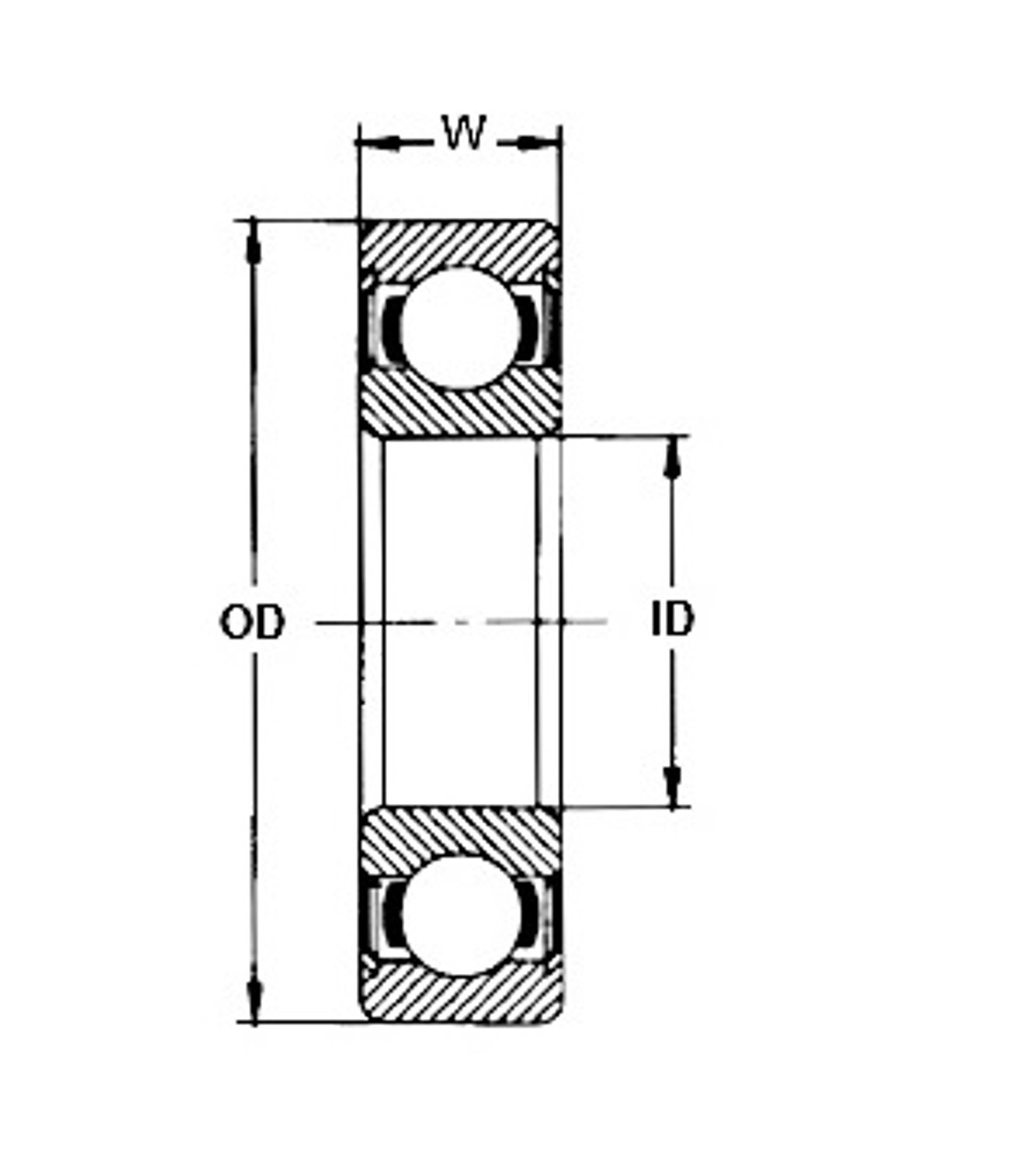

Sizes: ID 10mm x OD 35mm x W 11mm

Interchange : 6300ZZCM, 6300ZZC3, 6300ZC3, 6300.2ZR.C3, 6300SSC3, 6300-2ZJ1/C3, 300KSFFA3, C377300, 300KDDC3, 5U562, 6661K61

6300-2Z/C3 This single-row radial bearing has C3 radial internal clearance for radial slack between the inner and outer rings that is greater than CN (normal) to compensate for thermal expansion, 6300ZZC3 it has two rubber seals on outer ring to protect bearing from any alien objects and corrosion of internal components and they are non-contacts toward inner ring, it also has metal retainer, the retainer also referred to as the cage or separator, is used to separate and position the balls at equal intervals around the bearing raceways. The 6300-2ZJ1/C3 is precision ABEC1 or P0 international standard accuracy, 6300.2ZR.C3 is capable of carrying axial load and rotation at the same time as light duty ball bearing.

Rolling bearings use rolling elements to maintain the separation between moving parts to reduce rotational friction and support radial and axial loads. These elements can be one of the following types: ball, cylindrical, spherical, barrel, needle, spindle, or tapered. All rolling bearings are open, shielded, or sealed. Sealed and Shielded bearings are lubricated with oil or grease in the bearing factory, while open bearings are meant to be lubricated in place, with periodic reapplication of lubrication, based on use. The shield protects the working parts of the bearing from environmental debris that may be introduced and could reduce the ball bearing speed and lifespan. Rolling bearings are used in a range of applications from agricultural machinery to conveying equipment, electric motors, CNC machinery, trucks, mining equipment, train, robotics, dental equipment, elevators, rolling mills, ship rudder shafts, and aggregate crushers, among others.