Bearing Tolerances

Bearing Tolerances & Precision

Standardized bearing tolerancing is vital within all industries so that users know what they are purchasing. Trusted bearing manufacturers state a tolerance, and customers know exactly what they are receiving. This enables swift engineering, design, analysis, etc. Even though the tolerances are very similar, some slight variations do exist between standards. Annular Bearings Engineers Committee or ABEC and Deutsches Institut für Normung or DIN, are both commonly used within the super precision bearing industry.

ABEC was originated in the United States where DIN is a European standard, originating in Germany. International Standards Organization or ISO classes are also used, but these are not commonly used within super precision bearing realms. Below is a quick table outlining how the different precisions that may show up on bearings cross to each other. These are generally accepted equivalents within the precision bearing industry;

|

ANSI Standard 20* |

DIN 620* |

ISO 15, 355, 492, & 8443* |

|---|---|---|

|

ABEC 1 |

P0 |

|

|

ABEC 3 |

P6 |

Class 6 |

|

ABEC 5 |

P5 |

Class 5 |

|

ABEC 7 |

P4 |

Class 4 |

|

HG / UP** |

P3 |

|

|

ABEC 9 |

P2 |

Class 2 |

*Chamfer and other dimensions may be supported by other standards

**Some bearing manufactures have created their own custom tolerancing that are similar to DIN P3.

Engineering: The Tolerance of the bearing itself is only half of the equation.

Bearing Tolerance consists of Standard ABEC tolerancing correlated to user defined shaft and housing dimensions with suggested RPM adjustments provided.

Bearing Tolerance Leadership / Organization

The United States utilizes bearing standard tolerances approved by the American National Standards Institute (ANSI). The standards are presented to them from the American Bearing Manufacturers Association (ABMA). The standards are actually created and overseen by ABEC, a group under ABMA. ABEC and ABMA carry the weight of the industry in the USA on their shoulders as the primary care takers of bearing tolerancing. All of these organizations either have or listen to groups of individuals from various aspects of the bearing industry, including but not limited to; manufacturers, distributors, engineers, end users, etc.

In the 21st Century, all of these standards organizations, including DIN and ISO, work together for a common goal. This goal is achieved by users being able to trust in standards to successfully use precision bearings across many industries around the world. Precision bearing tolerance classes include tolerance for form, fit, function, and correlated running characteristics of bearings. This includes but is not limited to; Inner Diameter, Outer Diameter, Width, Radial Runout, Face Runout, Axial Runout, Profile of a surface, etc. For the ABEC precision classes, the higher the number the tighter the tolerance. In order from loose to tight tolerance; ABEC 1, ABEC 3, ABEC 5, ABEC 7, and ABEC 9.

Note that the DIN class is opposite of ABEC from a numerical standpoint. Listed from low precision to high precision; P0, P6, P5, P4, P3, and P2.

Bearing Tolerance Hints / Practicality

A good hint for engineers and purchasers is that there are larger gaps in pricing and precision between ABEC 3 and ABEC 5, as well as ABEC 5 and ABEC 7. This means the price and precision difference between ABEC 1 and ABEC 3 is less than ABEC 3 and ABEC 5. When precision machining of bearings was in its infancy, only ABEC 1 bearings were consistently produced. As machining prowess and technology increased, so did the consistency in super precision bearing machining and manufacturing. In the 21st century, ABEC 7 bearings are produced consistently, as well as ABEC 9 bearings fairly easily.

An interesting analogy and discussion about bearing precision classes vs. running capabilities is the 1-10 analogy. Every bearing actually has the same theoretical maximum RPM. A 6005TBR12P4 (ABEC7) bearing in precision ABEC 7, ABEC 5, or even ABEC 3 would all have the same theoretical maximum RPM rating. What changes is the opportunity to actually achieve the maximum RPM on a consistent basis. The analogy goes like this;

If 10 pieces of an 6005TBR12P6 (ABEC3) bearing were purchased, one could expect 3 of the 10 to achieve maximum capabilities. Concurrently, if one purchased 10 pieces of the same bearing but ABEC 5, one could expect 5 of the 10 to achieve maximum capabilities. So on and so forth. This is only a loose analogy to help engineers and purchasers understand the difference between precision classes. The higher the demand of reliability, runout, RPM, etc. the more the cost is justified for a higher precision bearing.

As one’s application reaches higher and higher RPM’s, every micron of parallelism, runout, surface profile, etc. all make a difference. To consistently run an application at high speeds, a super precision bearing in class ABEC 7 or higher would most certainly be suggested if not required.

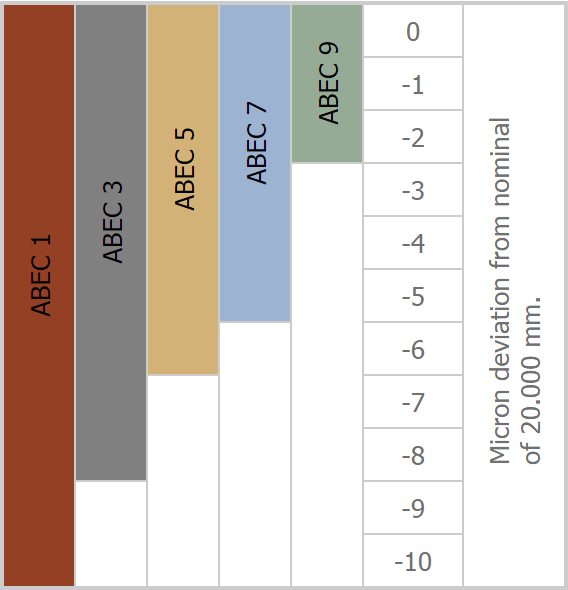

Bearing Tolerance Illustration

To illustrate the differences between the ABEC classes, please see the table to the left. The table shows the actual allowable micron deviations from nominal for a 20 mm inner diameter bearing. As you can see an ABEC 7 bearing only has a 5 micron tolerance window whereas an ABEC 1 has double that at 10 microns.